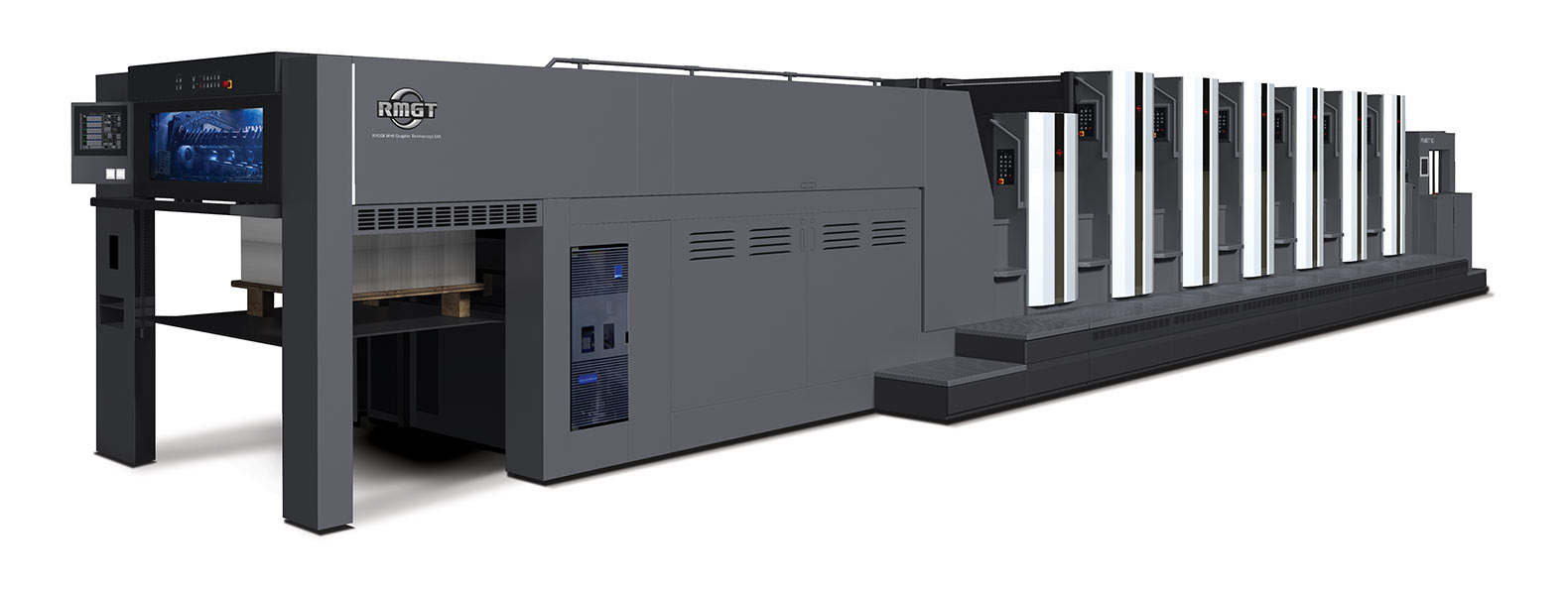

RM Machinery announces the immediate availability of the RMGT 1060 LX, the manufacturer’s 41-inch flagship press for packaging and commercial printers. The announcement is key for an industry that’s been rocked by steep new tariffs on printing equipment primarily imported from Germany and Japan. With presses in stock and ready for installation, printers can avoid such tariffs and potential roadblocks to success by turning to RM Machinery.

The federal government’s recent expansion of tariffs on industrial equipment has sent ripple effects through the global press market. Many companies have been burdened by extended lead times and overseas logistics, leading to massive delays and inflated costs for their North American customers.

“With supply chain issues and tariffs driving up costs and timelines, availability has become a serious competitive edge,” said Vice President of Sales Mike Stock. “Therefore, our customers can be up and running in weeks, not months. And, they’re avoiding six-figure tariff costs in the process. So, while others are waiting on shipments, we are installing presses.”

With 100 percent bonus depreciation back on the table for 2025, RMGT buyers can deduct the full purchase price of their press in the same tax year, delivering an immediate financial advantage. “Unlike our competitors, we have presses in stock and ready for installation this year,” said Stock. “Pair that with 100 percent bonus depreciation, and there’s never been a smarter time to upgrade your pressroom to an RMGT 1060 LX in 2025.”

The RMGT 1060 LX is engineered to reduce makeready times, cut paper waste and minimize labor requirements—key benefits in any market, but especially one in which good margins are hard to come by. With RMGT’s fifth generation fully automatic plate-changing system known as the SimulChanger, operators can complete makereadies in less than four minutes. Add energy savings up to 30 percent and RMGT presses deliver measurable performance at a significantly lower cost of ownership.

With a team of expert technicians, locally stocked parts and quarterly maintenance programs, RM Machinery’s service model is built to ensure uptime and protect the printer’s investment well beyond the installation.

“When you buy from RM Machinery, you’re not waiting on parts from overseas or hoping for remote support,” said Director of Customer Service Lloyd Molloy. “We’re here. We’re responsive. And we know these presses inside and out, because they’re built on the DNA of Mitsubishi’s legendary engineering.”

RMGT presses carry the best of Mitsubishi’s renowned technology, engineered for durability, stability and print quality that lasts. Combined with modern automation and pressroom integration, RM Machinery can now deliver the most attractive solution in the industry: Japanese technology without the price tag of a tariff.

© Copyright 2026 RM Machinery Inc.